Best Sellers

Built By Welders, For Welders

HTP started in a garage in 1989 when our founder got tired of machines that couldn’t keep up with real shop demands. We figured if you’re going to spend 10 hours a day behind a hood, your equipment should work as hard as you do. So we built welders that actually last—machines that fire up every morning without drama and lay down consistent beads shift after shift.

Today, we’re still that same stubborn company that tests every machine like our reputation depends on it (because it does). Our engineers aren’t just designers—they’re welders who’ve burned through enough rod to know what matters. When you call our support line, you’re talking to someone who’s actually run a bead, not reading from a script. We build our machines in the USA because we want to control every weld, every wire, every component that goes into them.

We’re not the biggest name in welding, and that’s fine by us. We’d rather focus on building machines that professionals trust when the job has to be done right. Whether you’re fabricating structural steel or doing precision TIG work on stainless, we make the tools that make your work possible. No fancy marketing speak, no inflated specs—just reliable welding equipment backed by people who understand what you do for a living.

Get the Latest Industry Insights

Technical articles, product updates, and welding tips delivered monthly.

Master Your Craft

HTP delivers welding equipment that works as hard as you do. No marketing fluff, no corner-cutting—just reliable machines backed by people who understand what you’re building.

Professional-Grade Equipment

Lifetime Technical Support

True Duty Cycle

Field-Proven Durability

Common Questions

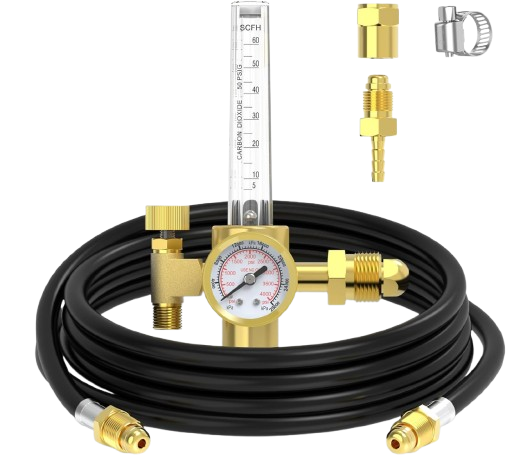

For steel welding, a 75% argon/25% CO2 mix works well for most applications. Stainless steel requires 98% argon/2% CO2 or tri-mix gases. Aluminum welding performs best with 100% argon. Gas selection affects arc stability, penetration, and final weld appearance.

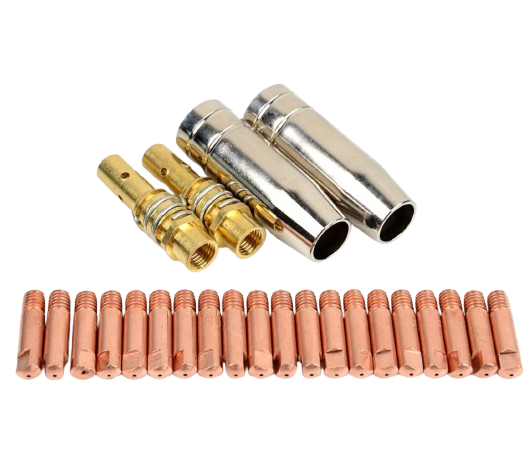

Contact tips typically need replacement every 4-8 hours of continuous welding, or when the hole becomes worn or spatter builds up. Nozzles should be cleaned regularly and replaced when damaged. Drive rolls last several months with proper tension but should be checked for wear grooves that can affect wire feeding.

TIG welding provides the most control for materials under 1/8 inch thick, allowing precise heat input. For MIG welding thin materials, use smaller diameter wire (.023″ or .030″), lower voltage settings, and faster travel speeds. Pulse settings, when available, help reduce heat input and prevent burn-through.

Intermittent arc problems typically result from poor ground connections, contaminated base metal, or incorrect voltage/wire speed settings. Check that the ground clamp makes solid contact with clean metal. Remove paint, rust, or oil from the welding area. Verify settings match the material thickness and wire diameter being used.

Wire feeding issues often stem from incorrect drive roll tension, worn contact tips, or kinked liner cables. Check that drive rolls match the wire diameter and type. Ensure the liner is the correct size and cut cleanly without burrs. Bird nesting at the drive rolls usually indicates too much tension or a feeding obstruction.

Regular cleaning of drive rolls and liner prevents wire feeding issues. Check and tighten all electrical connections monthly. Keep the cooling fan and vents clear of debris to prevent overheating. Replace worn consumables before they cause arc instability. Store machines in dry environments to prevent moisture damage to internal components.